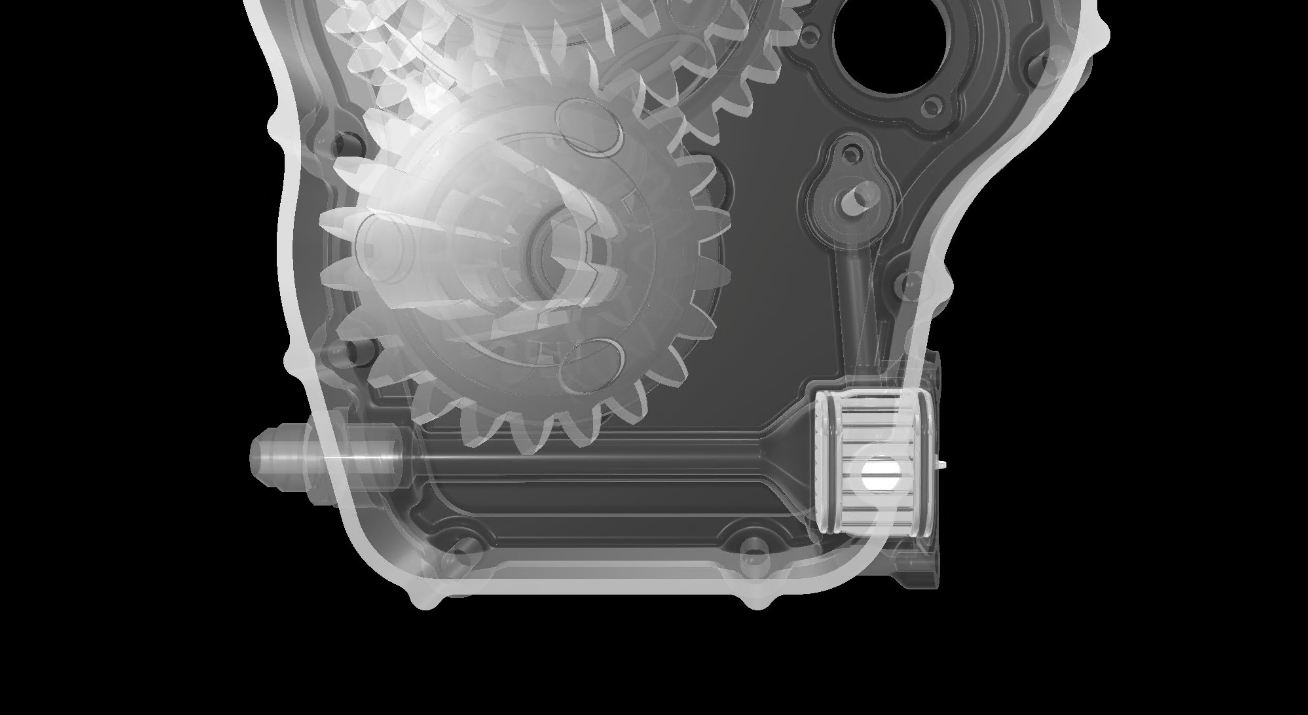

Today’s Formula 1 engines operate at 15,000 rpm and on a track like Monaco, drivers can complete up to 3,900 gearshifts during a grand prix [1]. The required meshing of all the gearsets to meet this demand generates a huge amount of friction and consequently heat, which can lead to component damage or failure. Lubrication systems help to reduce this friction by utilising oil to provide a film between the surfaces of interacting components.

Most motorsport and automotive applications use forced lubrication, where oil is circulated through an external cooling system to an oil-air heat exchanger. Here, the oil is cooled and then pumped back into the transmission. However, a more efficient approach is to extract the heat closer to where it is generated by using a cartridge heat exchanger. This avoids the need to transport the oil, reducing the amount of plumbing, leakages and associated pressure drop.

What are cartridge heat exchangers?

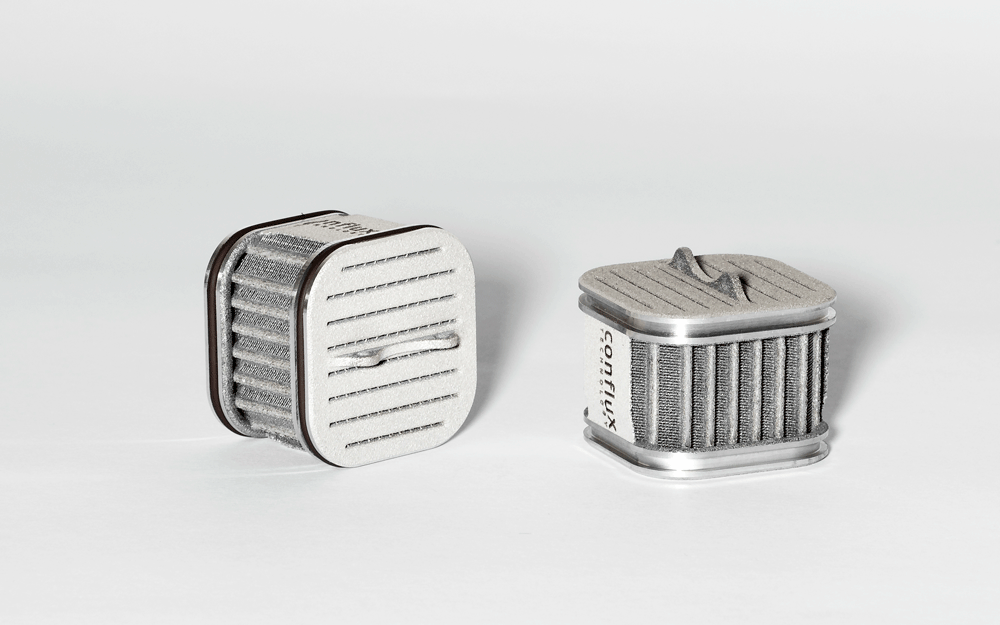

Cartridge heat exchangers are compact units that can be integrated into a system such as within the housing of a transmission. They were first developed in the early 1990s with tube and fin cores, and more recently microtubes. However, the labour involved in manufacturing these types of cores makes them extremely expensive.

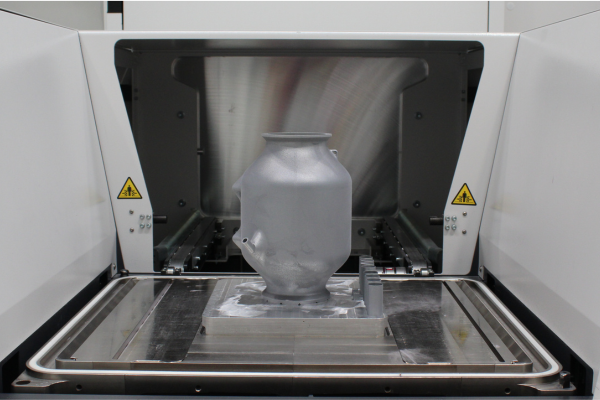

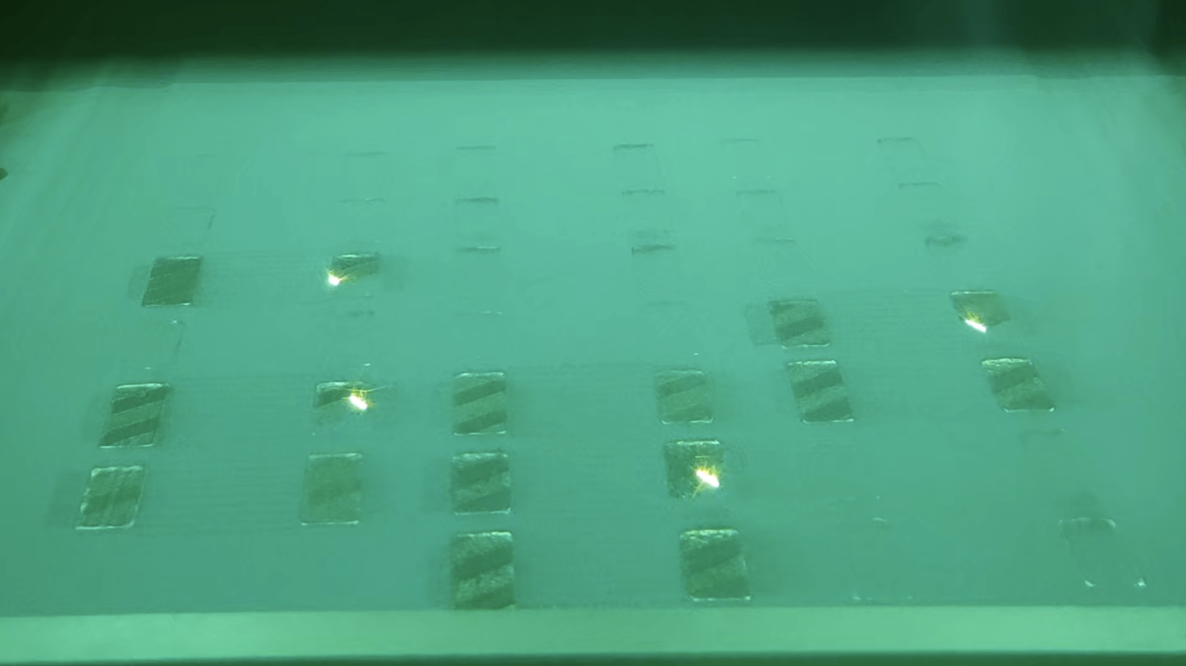

Additive manufacturing provides a more cost-effective alternative and although there are already projects focusing on 3D printed cartridge heat exchangers, these have not fully exploited the potential of additive manufacturing. Conflux Technology were recently tasked with utilising their additive manufacturing expertise to develop a new cartridge heat exchanger that achieves higher heat transfer performance than microtubes whilst also being customisable, serviceable, and low-cost.

‘Conventional cartridge heat exchangers are limited in many respects by their manufacturing costs,’ explains Michael Fuller, CEO at Conflux Technology. ‘But if done right, additive manufacturing can be a highly productive alternative that also offers the ability to design bespoke geometries suiting the properties of the fluid, maximising heat exchange. Our recent oil cooler that we developed with an industry partner achieved the same or better performance than an equivalent microtube heat exchanger without the high costs.’

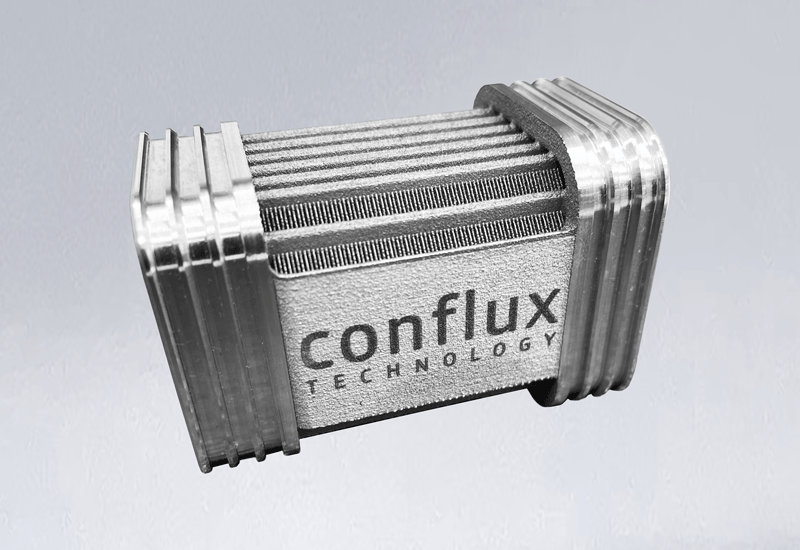

The Conflux Cartridge heat exchanger features a 3D printed core utilising patented CoreTM technology which provides lower pressure drop and higher heat transfer than microtubes. The compact unit can be inserted into a traditionally manufactured external part or casing, offering heat exchange close to the point of generation. The core itself is interchangeable, making it easy to replace or upgrade legacy cartridges, lowering maintenance costs and downtime.

Read about how our 3D printed cartridge heat exchanger boosts cooling performance

The benefits of additive manufacturing

Typically, heat exchangers are designed using lookup tables to identify the most suitable core from a standard catalogue. Often, this results in customers having to compromise on either the size or performance of the heat exchanger because it hasn’t been optimised for their specific application. Additive manufacturing on the other hand, offers much more flexibility, allowing engineers to tailor the internal geometry, surface area and size of the heat exchanger to meet customer requirements.

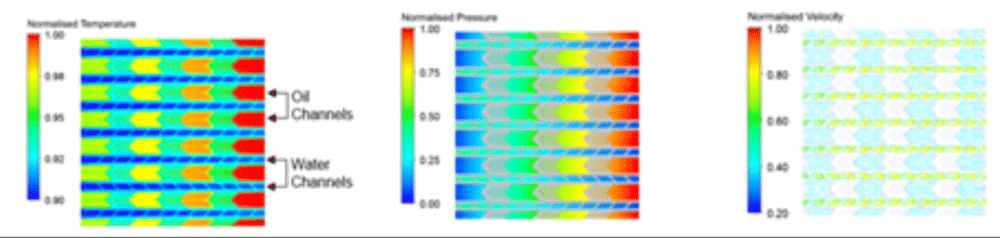

‘As a fluid moves through a heat exchanger, it changes temperature which, by definition, then changes its thermal conductivity and density,’ highlights Fuller. ‘Additive manufacturing gives us the capability to tune the geometry and optimise the surface area ratio to suit the fluid as it changes thermal-physical properties. This means we can intensify the rate of heat transfer, improve efficiency and boost overall performance.’

It's not just the number and size of fins that can be easily optimised with 3D printing, but the surface of the fins as well. To maximise heat flux, an effective technique is to promote mixing within the fluid. To achieve this, geometry is often placed in the path of the fluid to induce turbulence. However, this is not the most efficient approach as the resulting resistance of the flow can lead to an increase pressure drop. Alternatively, roughness can be added to the surface of the fins, which not only helps to induce micro vortices, but also disrupts the thermal boundary layer that can build up on surfaces.

Another tactic to increasing heat transfer is to maximise the area of active surfaces. ‘Almost all of the build volume of our cartridge heat exchanger is an active surface,’ says Dan Woodford, Chief Product Officer at Conflux Technology. ‘This means that every surface within the heat exchanger is achieving heat transfer - even the outer case surrounding the cartridge core. Minimising dead space is one way we exploit every opportunity to maximise heat transfer within the required volume.’

‘When developing a heat exchanger there are essentially three factors you need to consider,’ says Fuller. ‘You have the desired heat transfer between the two fluids, the pressure drop and the packaging or volumetric constraints. These are all interlinked so you have to compromise. For some applications, heat transfer is the priority, whereas other applications demand minimal pressure drop or a compact heat exchanger. Additive manufacturing is not limitless, but it does give you more freedom and allows for a more nuanced trade off analysis and optimisation.’

Applications for cartridge heat exchangers

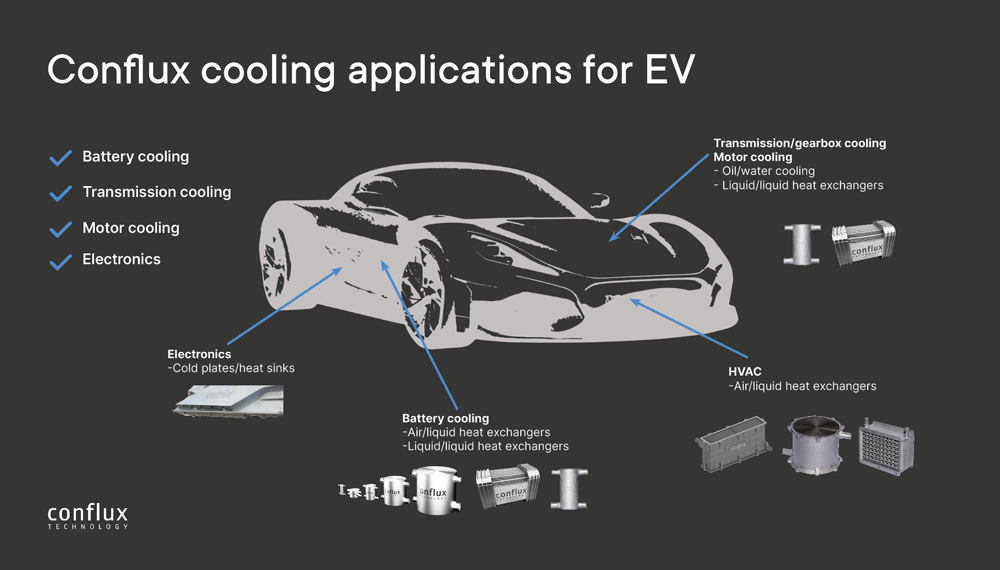

Conflux’s cartridge can bring a performance benefit to any application where heat exchange is required close to the heat source within a compact volume. This includes motorsport and automotive transmissions, electric vehicle powertrains, dyno gearboxes, aerospace hydraulics, hydrogen systems and refrigeration.

‘The customisability of 3D printing means we can design heat exchangers to fit into restricted areas, replacing either conventional cooling systems or cartridges, whilst achieving higher performance and lower costs than microtube heat exchangers,’ concludes Woodford.

Discover Conflux’s cooling applications for electric vehicles