Enhanced surface area density to volume ratio results in significantly higher thermal exchange performance, ensuring efficient heat transfer for your critical applications.

Micro-structures and complex internal geometries ensure low pressure drop, enhancing system performance through efficient, smooth fluid flow and optimal heat transfer.

Monolithic designs not only significantly reduce overall weight but also simplify maintenance with fewer parts to manage, streamlining system serviceability.

Morphed topology offers unmatched design freedom. Tailored to fit available spaces, providing flexibility in form factor and enabling seamless integration into a wide range of systems.

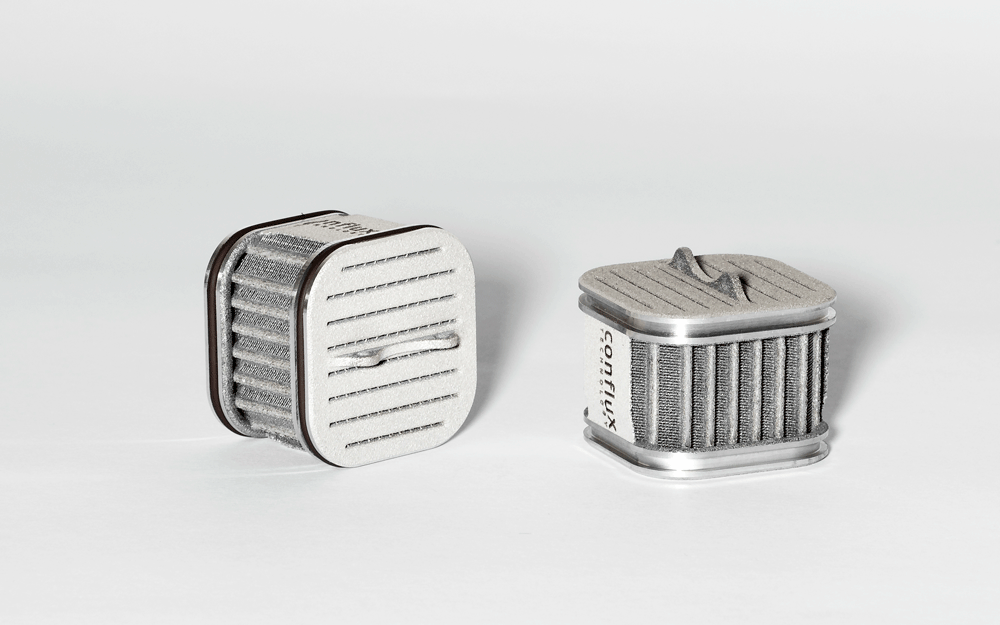

The Conflux Cartridge heat exchanger is a complex 3D printed core that can be embedded in a traditionally manufactured part or casing. The 'cartridge' features the patented technology of a Conflux Core™, resulting in a compact, serviceable, customisable, and interchangeable form of heat exchanger that offers a multitude of benefits across a wide range of applications.

The balance of thermal and hydraulic performance for complex thermal systems through scalable and low-cost production make it ideal for small energy systems. Furthermore, the ability to manufacture the cartridge heat exchanger in large batches with industrial powder bed fusion (PBF) machines keeps costs lower than equivalent traditionally manufactured options.

In systems where fouling or regular inspection must be accommodated, cartridges offer access for service, swap outs and upgrades, lowering maintenance costs and downtime.

A legacy cartridge can be replaced with Conflux Core™ technology for improved performance.

A conflux heat exchanger has our patented complex additive manufactured core – it’s a technology which outperforms the rest and provides lower pressure drop and higher heat transfer.

Small scale structures and internal geometries only possible with 3D printing provide precise control of the ratio of surface area presented to each fluid, optimizing heat transfer, turbulence and pressure drop.

The structural features are also active surfaces, minimizing dead space and increasing performance by volume.

The Conflux Cartridge, like all Conflux products, is designed to be configured. Conflux can deliver a test part to you quickly utilising our rapid sizing process, based on your boundary conditions.

For solutions with unique challenges, Conflux offers enhanced product development services. Utilising our patented Conflux Core™ technology we adapt designs to your specific application.

The Conflux team set out to design and manufacture a cartridge heat exchanger for oil cooling applications, to match or exceed an incumbent micro-tube heat exchanger for a transmission application. The team achieved remarkable results, demonstrating that the cartridge design could be applied to other applications and at a reduced price-point.