To meet the demands of extended build times and high-speed processing of challenging materials like copper, AMCM turned to Conflux Technology for an improved heat exchanger.

AMCM’s objectives were primarily two-fold:

With design freedoms on the overall shape and size, Conflux delivered a heat exchanger that exceeded the targets. The heat transfer solution provided greater heat transfer performance in a package just 7% of the original size, all while remaining cost-competitive, assuring AMCM of both efficiency and affordability.

“Achieving ultra-high performance is one part of the challenge – Conflux designs its parts and processes for serial Additive Manufacturing, ensuring we deliver a technically reliable and commercially viable product,” says Daniel Woodford, Chief Commercial Officer for Conflux Technology.

Thanks to Conflux's unique configuration and prototyping process, customers can swiftly obtain estimated performance ranges and tailored proof of concept builds. What would typically require up to 6 months in traditional manufacturing firms is streamlined to 3 months with Conflux's proprietary approach.

Each Conflux project commences with an initial meeting dedicated to grasping the customer's heat transfer challenges and their desired objectives. During this session, the team delved into discussions with AMCM about the boundary conditions, order of priorities, constraints and design assumptions.

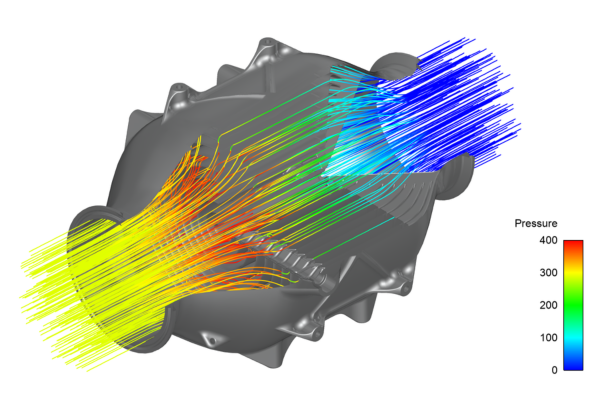

Following the receipt of requirements from AMCM's innovation and engineering team, with a focus on pressure drop and outlet gas temperature as key priorities, the Conflux team proceeded to present preliminary CFD simulations, complete with estimated performance ranges. A comprehensive report was produced, detailing the optimal configuration pertaining to fin size, design, density, and channel height to achieve the target performance. This document also encompassed overall package sizing, build estimation, and an evaluation of the technical and commercial feasibility for serial production.

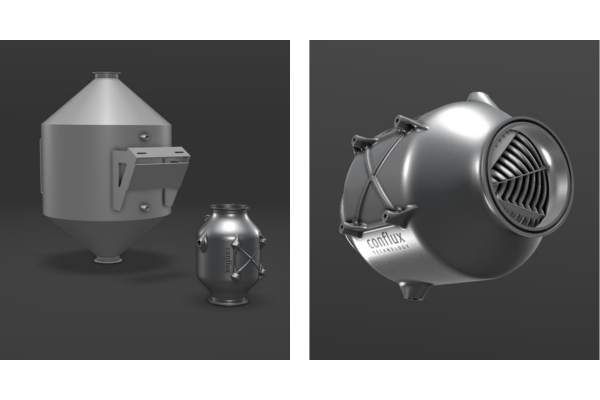

Pulling from Conflux’s library of additive manufacturing optimized designs, the design engineers ultimately selected a core base model that has proven successful in other applications and tailored the packaging requirements to fit within the existing space of the incumbent heat exchanger.

Multiple elements were configured including form factor, ducts, vanes and outlets to match connections for installation. For example, AMCM requested a larger diameter of the ducts to allow for better flow rates with lesser pressure loss. These and other features were adapted and refined to ensure performance enhancement, practical requirements and specific fit for end use in the final application.

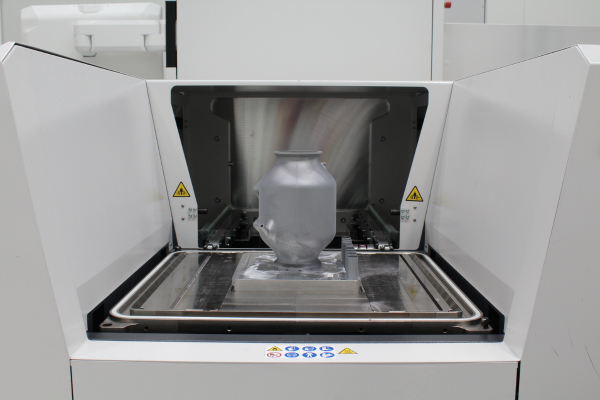

Conflux is capable of rapidly designing, manufacturing and delivering a proof-of-concept prototype due to their local manufacturing facility, equipped with several 3d printing machines including the EOS M300.

The unique demands of the inert gas in this heat exchanger necessitated the strictest levels of cleanliness throughout the build and post-processing. Conflux’s proprietary post-processing techniques, coupled with AS9100D certification, assure customers of the reliability of its heat exchangers.

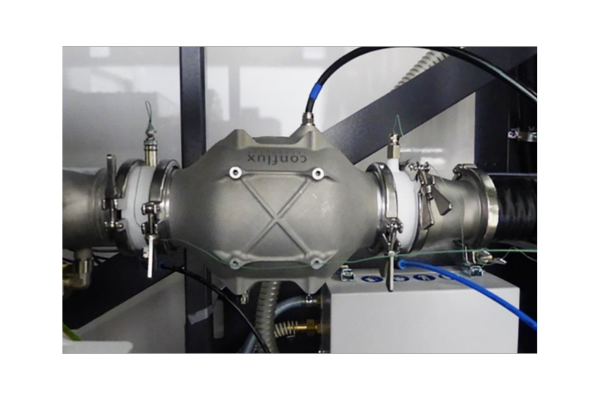

With the prototype build passing Conflux’s rigorous internal checks, AMCM conducted their own in-house testing on a production M 4K machine. After passing performance and cleanliness tests, AMCM confirmed a serial production order.

Conflux provided AMCM with an argon gas heat exchanger that met their requirements and more.

With the serial production order, AMCM will retrofit existing M 4K machines around the world, upgrading its thermal management system and providing its customers with the latest in heat transfer technology.

In the pursuit of advancing additive manufacturing applications, the engagement between AMCM and Conflux has been a resounding success. The concept of applying DfAM principles to 3D print a heat exchanger, which ultimately integrated into another 3D printing machine, serves as a testament to the remarkable self-replicating potential of this advanced technology.

Conflux is now in serial production for AMCM, ushering in a new era of heat transfer technology for their M 4K machines. This project underscores Conflux's unique capabilities in additive manufacturing and its commitment to pushing the boundaries of what 3D metal printing machines can achieve.