Enhanced surface area density to volume ratio results in significantly higher thermal exchange performance, ensuring efficient heat transfer for your critical applications.

Micro-structures and complex internal geometries ensure low pressure drop, enhancing system performance through efficient, smooth fluid flow and optimal heat transfer.

Monolithic designs not only significantly reduce overall weight but also simplify maintenance with fewer parts to manage, streamlining system serviceability.

Morphed topology offers unmatched design freedom. Tailored to fit available spaces, providing flexibility in form factor and enabling seamless integration into a wide range of systems.

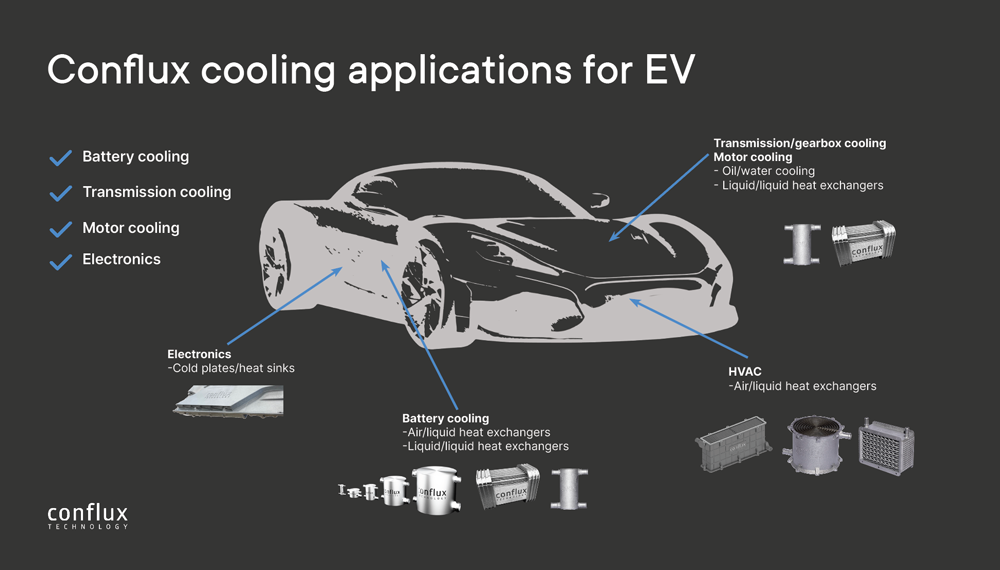

The possibilities of what additive manufacturing (AM) can deliver in terms of design, performance and production are now being investigated by electric vehicle (EV) manufacturers around the world.

With the design flexibility that AM enables, EV manufacturers can achieve lighter weight and more compact heat exchangers. Time from design to build is substantially decreased, allowing for rapid prototyping straight into reliable serial production.

Electric vehicles require both cooling and heating to maintain battery temperatures at the optimum window to ensure performance and range. Additive manufacturing opportunities for thermal control in EV is a topic we discuss in this article.

Dive into the world of electric vehicle thermal management with our comprehensive eBook, "Cooling the Future: Innovations in Electric Powertrain Thermal Management." This essential guide is your key to understanding the cutting-edge technologies shaping the future of EV cooling.

By downloading this eBook, you'll gain insights into:

Enhance your understanding of EV thermal management by downloading our eBook now.

Battery thermal management

Powertrain cooling

Transmission cooling

Motorwinding cooling

Chiller

HVAC heater

Heatsink / vapour chamber

Cold plate

Oil / water heat exchanger

Liquid/liquid heat exchanger

Air/Liquid heat exchanger

Electric vehicle heat exchanger

At the heart of these electric Vertical Take Off and Landing (eVTOL) vehicles lies the electric powertrain. This consists of a lithium-ion battery along with high performance motors and inverters which generate the necessary lift and propulsion. There are a variety of different powertrain concepts currently being developed, however they all share the same thermal management challenges that come with high power and high voltage electronics.