Enhanced surface area density to volume ratio results in significantly higher thermal exchange performance, ensuring efficient heat transfer for your critical applications.

Micro-structures and complex internal geometries ensure low pressure drop, enhancing system performance through efficient, smooth fluid flow and optimal heat transfer.

Monolithic designs not only significantly reduce overall weight but also simplify maintenance with fewer parts to manage, streamlining system serviceability.

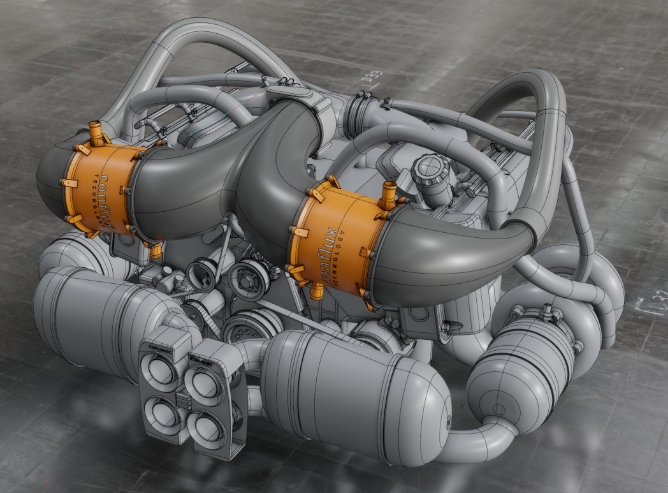

Morphed topology offers unmatched design freedom. Tailored to fit available spaces, providing flexibility in form factor and enabling seamless integration into a wide range of systems.

Our ultra-high performance WCAC delivers significant reductions in core volume, air-side pressure drop and weight.

When benchmarked against the leading microtube WCAC, for the same heat transfer we saw:

82% reduction in water side pressure drop

39% reduction in wet weight

24% reduction in air-side pressure drop

15% smaller core volume

How could improvements like these help your team?

Our design process facilitates scaling, configuration, and the manufacture of heat exchangers unique to your boundary conditions, performance and packaging requirements.

Complex geometries and micro features unachievable with traditional manufacturing drive the core performance, alongside fins and thin wall designs that accomodate the changing fluid dynamics throughout the heat exchanger.

The high surface area to mass ratio inside the core is enhanced by a holistic design that optimises fluid distribution and flow, providing more heat exchange per unit of weight or volume.

The Conflux WCAC is designed to be configured. Conflux can deliver a test part to you quickly utilising our rapid sizing process, based on your boundary conditions.