What is a Boundary Layer?

Most people working with heat exchangers are aware of the concept of the boundary layer. Put simply, these are thin layers that form in fluids at the interface with solid boundaries. They occur whenever fluid flows through a channel or over a surface. In this thin layer, fluid velocity changes from zero at the wall surface (referred to as the no-slip condition) to some freestream velocity a certain distance away from the wall.

A thick boundary layer has a negative effect on heat exchanger performance as it impedes heat transfer. Think of it like a blanket, thicker the blanket, the higher the insulation. This is not ideal for heat exchangers as the main objective is to ‘transfer heat between fluids separated by solid surfaces.

There are typically two main types of boundary layers:

Laminar Boundary Layer:

In a laminar boundary layer, the fluid moves smoothly and orderly in parallel streamlines. The flow remains in layers with minimal mixing, and heat transfer is poor. Laminar boundary layers are more common at lower flow velocities and for viscous fluids.Turbulent Boundary Layer:

In a turbulent boundary layer, the fluid flow becomes chaotic with swirling and mixing of fluid particles. This chaotic motion enhances heat transfer and can reduce the thickness of the boundary layer. Turbulent boundary layers are often preferred in heat exchanger and other engineering applications because they provide more efficient heat transfer.

The thickness of the boundary layer, as well as its transition from laminar to turbulent, depends on factors such as the fluid properties, the surface roughness, and the flow velocity.

What is Turbulent Flow?

Turbulent flow is a type of fluid flow characterized by chaotic, irregular, and random motion of fluid particles. In turbulent flow, the fluid moves in a disorderly fashion, with the velocity, pressure, and other flow parameters fluctuating rapidly in both magnitude and direction. This chaotic behavior creates vortices, swirls, and eddies in the fluid, leading to mixing and enhanced heat and mass transfer.

Some key characteristics of turbulent flow include:

Random Motion:

Unlike laminar flow, where fluid particles move in smooth, parallel layers, turbulent flow exhibits random and irregular motion. Fluid particles in a turbulent flow exhibit a wide range of velocities and directions.Eddies and Vortices:

Turbulent flow is characterized by the formation of eddies and vortices of varying sizes. These structures are responsible for mixing and enhancing transport properties.Increased Heat and Mass Transfer:

Turbulent flow is more effective at heat and mass transfer compared to laminar flow. The chaotic motion of fluid particles promotes the mixing of different components within the fluid.Higher Drag:

Turbulent flow typically results in higher drag or resistance compared to laminar flow. This is due to the increased energy required to maintain the chaotic motion of the fluid.

How do Conflux Heat Exchangers handle boundary layer and turbulent flow?

Turbulent flow is generally preferred in heat exchanger design for the increased heat transfer capabilities as mentioned above. It’s generally associated with higher pressure drop – however this penalty is often justified by the heat transfer performance gain. The swirling and diffusive characteristics of turbulent flow enhances heat transfer. Mixing induced by turbulent flow can also disrupt the growth of boundary layer on heat exchanger core surfaces. However, turbulent flow is often associated with higher pressure drop.

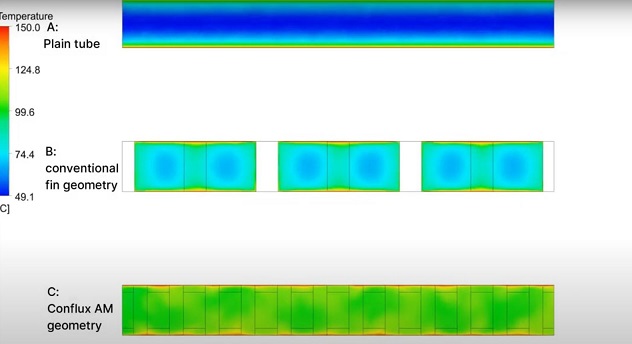

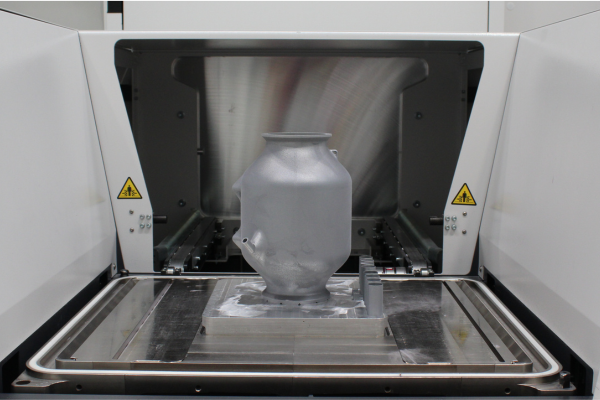

Through our patented complex geometries and by taking advantage of additive manufacturing, we have increased efficiency of additively manufactured heat exchangers. Our internal geometry promotes turbulent flow which helps to reduce thickness of the boundary layer within our heat exchanger core.

As mentioned, reducing the size of the boundary layer and promoting turbulent flow can enhance the performance of a heat exchanger. This can be achieved through the following:

Increase fluid velocity

Speeding up fluid flow through core is an effective way of increasing heat transfer. However, appropriate balance between heat transfer gain and pressure drop penalty needs to be considered. Having closely packed fins and multipass configuration can increase fluid velocity through core.

Mixing enhancement features

Addition of features such as turbulators, baffles, and corrugation can further enhance heat transfer.

Conflux Technology has been producing superior heat exchangers with high heat transfer and minimum pressure drop. This is realized through our patented complex geometries, extensive parameters optimization, and by leveraging Additive Manufacturing process and its intrinsic surface roughness.