“Well, we already have an AM machine on which the team has tried to develop heat exchangers. We have found that using conventional design approaches has not yielded the benefits we had expected in our testing.” We often hear something like this.

Over the years, we have met with companies that already have AM machines, some gathering dust and some in use within a range of different sectors. At some point they have tried to make a heat exchanger, they would print out a few conventionally designed units and note the lack of any significant performance or size benefits and move on.

Additive manufacturing allows us designs not available with conventional brazed or subtractive manufacturing approaches. Through our expertise and experience, Conflux Technology can leverage our configurable products and our design library of complex geometries to produce heat exchangers that exceed the performance of other leading HXs that are currently available.

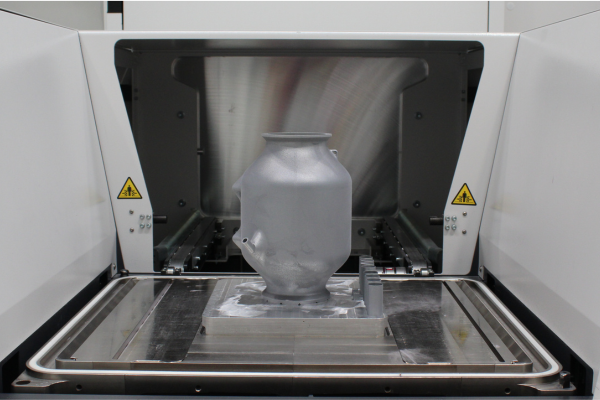

When we start developing a heat exchanger, we have a volume we want to fill and some boundary conditions we must achieve. Our DfAM and Simulation team explore if those benchmarks can be reached, more often than not, they can be. The simulation team will produce a design brief that our DFAM team uses to produce an initial design. Once we have an initial design, our DfAM team then talks to our additive manufacturing experts about their design. There is often a bit of back and forth as we move from design into a physical build. We then qualify the build through inspection involving our own purpose-built Conflux Quantify™ and qualify the performance through calorimetric testing. Finally, we correlate the results with our simulation models, bringing a design from conception to a physical product.

Our team not only has a clear understanding of their task but a formidable knowledge within their field. We have a robust understanding of the AM processes we use and can push them further than they were originally designed to do. Our performance results out-benchmarked current leading heat exchangers already on the market.